MPM, expert in transforming plastic materials.

The MPM Company is specialized in the injection of thermoplastic parts and ensures total control over the realization of your industrial projects, from products study to serial production. A coating workshop allows us to ensure a complete offer and to deliver sub-assemblies to our clients (marking, machining, assembly, ultrasonic welding).

- Projects management

- Products/process conception

- Production: injection and assembly

- Equipment maintenance

3 engagements in quality

-

Products Quality

MPM guarantees the quality of its products thanks to adjusted means such as a total traceability, statistical monitoring of our productions and capabilities study.

-

Environment friendly

To be in line with a respectful approach to the environment, we invest in waste recycling and energy consumption optimization.

-

Customers satisfaction

We make a priority of satisfying the client, to do so, we benefit from control devices which guarantee the conformity of the delivered parts.

-

Certification of quality

Download the documents below :

Download the documents below :

Certification ISO 9001

Certification ISO 14001

Certification EN 9100

MPM has production means insuring that our clients and their needs reach satisfaction

Our workshops process the largest range of plastic materials for technical parts and aspect parts.-

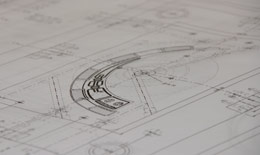

Design office

Commercial team, Project managers, CAD designer, Tests and prototypes, Industrialization manager

-

Laboratory

A fully equipped laboratory to perform durability tests, perform impact tests, perform operational tests, produce test reports guaranteeing the quality of our products

-

Equipment

35 injection molding machines from 25 to 450 tons, 1 air blowing injection molding machine, 1 vertical press, 1 spotting press, 1 EDM machine, 4 ultrasonic welding machines, 1 pad printing machine, 1 three axis gasket dispensing machine...

-

Monitoring

The various monitoring means of MPM: Dimensional measurements, Profile projectors, Colorimetry, MPM has implemented a quality assurance for all of its products...

-

Computer equipment

High tech computing resources : CAD stations (Pro-Engineer), Moldflow software + displacement calculation, CAPC SAP.